For Nicaraguans, the idea of implementing new technological solutions for small and mid sized agro-operations is still far from being a reality; this is mainly due to the high cost that this would mean for these businesses to modernize their work equipment.

For this project, we centered around an agricultural operating business that is dedicated to the production and export of dragon fruit.

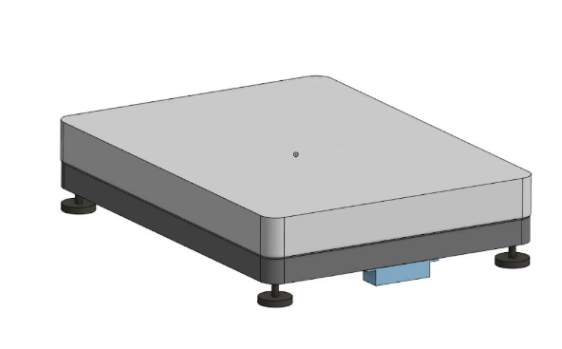

The client came to us in search of a solution for a problem they’ve been experiencing with weighing their products. During the control of the operation, there has been a constant problem with weight traceability in the processing areas. Currently, weighings are carried out manually on a scale that indicates the weight of the product on a display; the data (weight, type, and batch number) is then written on a logbook by hand. At the end of the day, a person has to enter the collected data in the computer.